Efficient Induction-Based Engine Chamber

The induction thermo chamber replaces combustion with controlled thermal loading, offering efficiency gains, lower emissions, easy maintenance, and compatibility with PW500-class and TFE-731 engines.

[ Electric Heat, Without Combustion ]

Thermal Power Through Electricity

An induction-based thermo chamber generates precise electric heat for advanced engine testing without combustion and scalability.

Uses electricity to generate heat, eliminating the need for combustion.

Heat is produced directly inside the chamber using induction technology.

Heat delivered to the engine/test section is precise and adjustable

Heated air flows consistently to simulate engine conditions.

Electric control ensures repeatable thermal profiles for accurate testing.

No flames or exhaust, making it cleaner and easier to scale for different engines.

[ Induction Heating ]

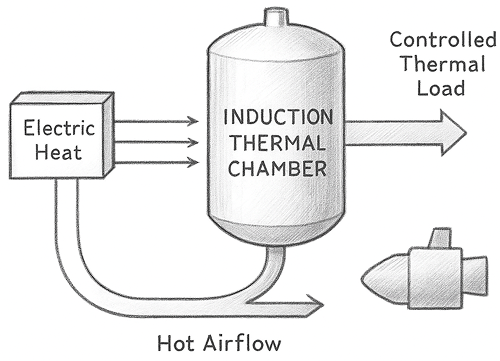

From Electricity to Controlled Thermal Load

1

Electric Power Input

System receives electrical power instead of fuel, supplying energy to generate heat in the thermal chamber.

2

Induction Heating Activation

Electric induction produces heat directly within chamber materials, eliminating external flames or traditional burners.

3

Combustion Eliminated

No fuel combustion, flame stabilization, or exhaust management is required, simplifying the system operation.

4

Thermal Output Control

Heat intensity is precisely controlled by adjusting electrical input parameters for accurate thermal management.

5

Controlled Thermal Loading

Regulated heat is precisely delivered as a controlled thermal load, ensuring consistent and safe testing conditions.

6

Repeatable Test Conditions

Consistent thermal profiles enable accurate and repeatable engine testing cycles without variability.

Status: Scaled prototype in final design phase; multi-kilowatt induction chamber validated.

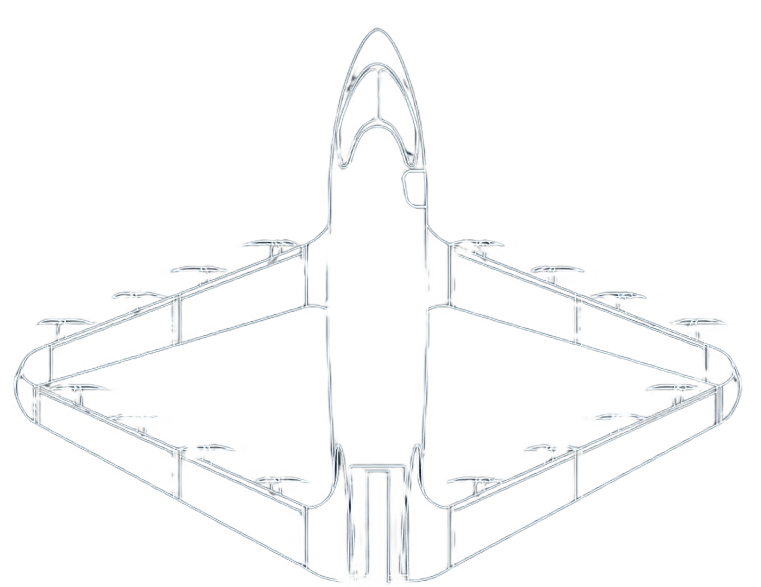

[ Engine Compatibility]

Highlight compatibility with engines

Designed to integrate across multiple engine platforms, the system can be scaled and adapted for PW500-class, TFE-731, and similar propulsion architectures.

[ Core Benefits ]

Key Technical Claims

-01-

Efficiency Potential

Optimized energy flow and system design maximize output while minimizing input, enhancing performance, reducing wastage, and ensuring higher operational efficiency across all operating conditions.

-02-

Emissions Reduction

By replacing combustion with controlled processes, harmful emissions are minimized, lowering carbon footprint, improving environmental compliance, and promoting cleaner, sustainable operation throughout system lifecycle.

-03-

Maintenance Benefits

Simplified design with fewer moving parts reduces wear, extends component lifespan, lowers maintenance frequency, decreases operational costs, and ensures smoother, reliable system performance over time.